Sample A is softer as indicated by the significantly lower peak force values compared to Sample B. The internal structure of the bread has changed during the four-hour staling process to become more firm and rigid. The consumer will obviously notice the higher resistance to biting and chewing the bread slices that constitute Sample B.

Plotting the data using force versus distance for the same tests produces the graph in Figure 3, making it easy to perform mathematical calculations that quantify the amount of work done to compress the bread slices. The area under each curve is the equivalent work value for Sample A and Sample B respectively during the first compression cycle. Unit of measurement for work done is millijoules. Sample A has a value of 4.54 while Sample B is 9.75. This calculation confirms that the consumer will easily sense the difference between fresh and stale bread slices.

Springiness Index

The final parameter used to evaluate the samples is springiness. This is technically defined as the ratio of spring-back distance compared to the maximum deformation. Both samples recovered almost completely after each cycle, therefore, the spring-back distance is close to the 4 mm compression distance. Springiness in both cases is relatively close to 1.

Springiness index is the ratio of springiness to the actual deformation after the completion of cycle 1. Since each slice recovered substantially to its original thickness, the actual deformation of each slice was relatively small compared to the thickness of the slice. Therefore, the springiness index will be a numerical value much greater than 1. Sample A is 5.08 and Sample B is 5.34. Comparatively speaking, fresh and stale slices were fairly similar.

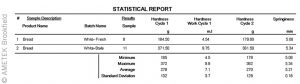

The obvious advantage of TPA is the ability to numerically quantify behavior of the bread slices using deformation tests that simulate biting and chewing. (See the compiled measurement data in Table 1.) Comparing test data to standards for freshness and staling provides a meaningful yardstick to ensure that each batch will meet customer expectations.

McGregor is director of high-end lab instrument sales at AMETEK Brookfield, Instrumentation & Specialty Controls Division. Reach him at [email protected]. Chiang is sales manager, texture, for the company. Reach him at [email protected].

ACCESS THE FULL VERSION OF THIS ARTICLE

To view this article and gain unlimited access to premium content on the FQ&S website, register for your FREE account. Build your profile and create a personalized experience today! Sign up is easy!

GET STARTED

Already have an account? LOGIN