Daly adds, “The food processor must ask the question: ‘Am I equipped with the latest cleaning and sanitizing technology and expertise to effectively manage and control the threat of foodborne pathogen contamination?’”

As facilities manage their processes, good manufacturing practices (GMP), and various intervention programs, they must also manage and optimize cleaning and sanitizing performance levels during the sanitation operation.

GMPs are programs that comprise the basic, universal steps and procedures that control operating conditions within establishments and ensure favorable conditions for safe food production. They are the control factors that relate to the entire operation and are not process specific. GMPs include such programs as pest control, recall procedures, construction/maintenance, and sanitation.

Management Critical to Success

“Although sanitation product technology and specific pathogen reduction programs are readily acquired, it is the qualified management of these programs and practices that are absolutely essential to attain that comfort level and control in your sanitation operation,” Daley said. “This is what outsourcing provides.”

Management is crucial to the success of these programs, Daley said. “The technology and procedures in place are only as good as the individuals who really drive the program.”

Dave Boyer, New Oxford Foods’ complex manager, agrees. With 520 employees processing nine million turkeys each year, New Oxford Foods, located in New Oxford, Pa., has outsourced its sanitation services since 1996.

Another key to a successful outsourcing relationship involves clear communication and a good relationship with the internal management team, Boyer said. “If we have issues, we get them on the table and get them fixed.”

Times are changing. Third-party plant audits are increasing, and companies face mounting pressure to document every aspect of their procedures and processes to prove that they can meet all of the required standards, Boyer said.

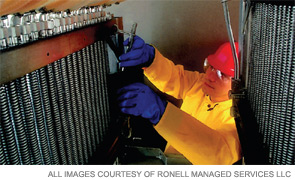

Boyer added that he appreciates the fact that their contract sanitation partners are more adept at using the most up-to-date cleaning processes and newest chemicals on the market.

Although sanitation product technology and specific pathogen reduction programs are readily acquired, it is the qualified management of these programs and practices that are absolutely essential to attain that comfort level and control in your sanitation operation. This is what outsourcing provides.

—Jim Daley, Ronell Managed Services

“They see a lot that we don’t see because they work with so many different plants and environments; that is an expertise and value that can’t be quantified,” Boyer said. “We’re a poultry company, not a sanitation company. And economically, outsourcing remains a good decision as well.”

Jeremy Russell, director of communications and government relations for the National Meat Association, a nonprofit trade association, said that in his 12 years in his position, he has “seen a lot of changes in the industry, but good sanitation remains the foundation to a clean plant and clean product.” It is up to an individual company to determine if outsourcing sanitation would be appropriate, he said.

Invest in Sanitary Designs

To get the best results from sanitation crews, Russell encourages processors to invest in equipment with the best sanitary design. “Investing in replacing old equipment can make a big difference to cleanliness and the ease with which it is cleaned.”

The American Meat Institute developed 10 principles of sanitary design that Russell believes are essential to reducing foodborne bacteria and contamination. A few key factors include:

• No “niches”—equipment should be free of cracks, recesses, pits, corrosion, and so on;

• Hygienically designed maintenance enclosures—push buttons and touch screens, for example—should be designed to ensure that no food, water, or other liquid penetrates or accumulates in and around the enclosures; and

ACCESS THE FULL VERSION OF THIS ARTICLE

To view this article and gain unlimited access to premium content on the FQ&S website, register for your FREE account. Build your profile and create a personalized experience today! Sign up is easy!

GET STARTED

Already have an account? LOGIN